AUTOMOTIVE SURFACE PREPARATION

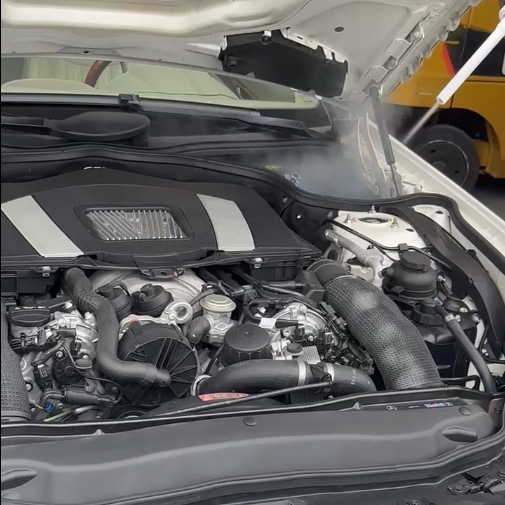

Dry ice blasting prepares surfaces with a dry process that will not damage surface dimensions.

Dry ice blasting eliminates the need for aqueous or chemical solutions for surface preparation.

The process removes contaminants from delicate plastic surfaces and is also used to remove heavy contaminant buildup on metal and steel surfaces for immediate repair or non-destructive testing.

Dry ice blasting will not leave residue on surfaces or cause grit entrapment. This results in higher quality parts and more accurate measurements during testing.